Neville Chamberlain once famously wrote “There are no winners in war”. Well, for over fifty years Translift have been waging war on wasted space, and there have been thousands of winners. Winners who have saved space, money and time, thanks to the innovative products and solutions from Translift.

Companies such as DCS, the UK’s largest distributor of health, beauty and household brands, first turned to the Bendi in 1998 in order to increase warehouse capacity compared to reach trucks. Now nearly twenty years later, there are over twenty Bendi’s in use throughout the DCS operation.

But it is not just fleet users who have won with Translift. The introduction of a single Bendi is sometimes all it takes to help companies overcome space and productivity issues. One such company being Rochford Garden Machinery, who by introducing a Bendi B318 gained 30% more pallet positions. The company experienced significant improvements in operating efficiencies by unloading the products outside. This brought them into the warehouse and placed them directly in the racking in one operation.

Wasted space? Why you might need increased capacity!

There are all kinds of reasons why a company may need the extra space. Below are how a Translift product can increase their storage capacity and combatted wasted space:

- They are struggling for space due to business growth and increased sales. However, they don’t want the additional costs of moving or extending the warehouse.

- They want to reduce the number of trucks in their fleet – a Bendi works great both inside and outdoors unloading.

- They are a manufacturing company who needs to increase the floor space available in order to introduce new machinery.

- New product ranges mean they have insufficient pallet racking or shelving space.

- They are a Third Party Logistics (3PL) company and require to accommodate additional contracts.

Whatever the reason, you can be sure that there is now a Translift product to suit most applications and budgets. After listening to the needs of our customers and trade partners over the past fifty years we a have a solution for all applications. Make sure you don’t have wasted space.

Mini Marvel For Asda

Asda is another perfect example of a company who has benefited greatly from the Bendi product.

Through engineering innovation and design, supermarket chain Asda has been able to save on average 40% space. In its ‘back of house’ high bay racking areas in each store we have reduced aisle widths to less than 2m and operating VNA Bendi trucks sorting out their wasted space.

By replacing reach and counterbalance trucks and opting for a fully remanufactured rear wheel drive Bendi model; a design which was patented by Translift Bendi in the 1980s, Asda now has the specification for indoor and outdoor use.

With the first Bendi machines delivered to Frome followed by Capehill, Motherwell and Glasgow some ten years ago, it is remarkable that today many of Asda’s 365 stores, nationwide, use Bendi.

According to Simon Grass of Asda, it was a natural progression. “We had been working with Bendi for many years and their team continually looks to support our operations through cost effective, space saving solutions. They truly understand what we needed to achieve and worked with us to meet those requirements.” With the first introduction to store of the new Mini Bendi six years ago, Asda looked to make even greater storage space savings.

Pedestrian Truck

Launched in 2011, the Mini Bendi was developed in answer to the call from the industry for a smaller, lighter, pedestrian controlled machine. that didn’t necessarily have the speed or reach of a conventional Bendi but could accommodate the UK style perimeter based pallets. Working closely with Asda, it was a natural step for Bendi to develop a pedestrian truck that provided the versatility and safety required regardless of industry sector.

Bendi has recently added two more customer driven variants to the mini range. The first is a ride-on platform for customers who wish to use the Mini Bendi but also need then to transport pallets over longer distances. The simple drop down platform controls the speed variance for both rider and pedestrian operated modes.

The Mini Bendi is also now available with a self-raising control arm. This arm fits the operational and ergonomic needs while the truck is in use. Then the arm raises vertically when the truck is not in use, thus saving even more space when parked.

“The Mini Bendi pedestrian articulated forklift truck is an impressive feat of design ingenuity,” continues Grass. “It is a much smaller, lighter machine than the other trucks in the Bendi range. Yet the Mini offers superior levels of safety and functionality previously considered unattainable in our back of house warehousing environment.”

Introducing FluX and MaxX from Translift Hubtex

With the company celebrating its 35-year anniversary, Hubtex has launched two new game-changing products. The MaxX and FluX have been released to mark the opening of its new production facility in Fulda, Germany. The introduction of the new machines will bolster its already impressive product portfolio by adding modular multidirectional sideloaders into the growing entry-level pricing bracket. Boasting a spacious operators cab, a multifunction joystick, a new-generation info display and easy battery change, the MaxX and FluX are ergonomically designed for both indoor and outdoor use.

FluX – the New Multidirectional Counterbalance Forklift

Hubtex has launched an industry first with its multidirectional counterbalance forklift. The forklift features a patented steering technology that goes by the name of FluX. The truck is available in two load-capacity classes – 3,000 kg and 4,000 kg – with a 48-volt power system and four-wheel chassis.

It is designed to be used as both a conventional front loading counterbalance forklift as well as a sideloader. The forklift is especially suited to transporting standard type pallets and long loads. In addition to its fast operating speed of up to 12 km/h, Hubtex’s patented HX steering system means that the FluX doesn’t have to stop to switch from travelling forwards to sideways like existing trucks. The FluX can change direction with all wheels steering together. This is done in a way that causes minimum wear and tear to the vehicle and can save a substantial amount of time, especially when the truck is used for handling both long loads and pallets.

Flexible Handling of Long Loads with MaxX

MaxX, the new electric multidirectional sideloader from Hubtex is available in three variants. With a load capacity of 3,000 kg and a powerful 48-volt power unit, or with a load capacity of 4,500 kg and a 48 or 80-volt power unit.

The four-wheel chassis allows the vehicle to achieve tighter turns while also offering higher residual load capacities. Able to operate for five to eight hours at a max speed of up to 11 km/h, the truck can be used for multiple shifts thanks to its quick and easy battery change method.

Another Successful Night For Translift At The “Forklift Oscars”

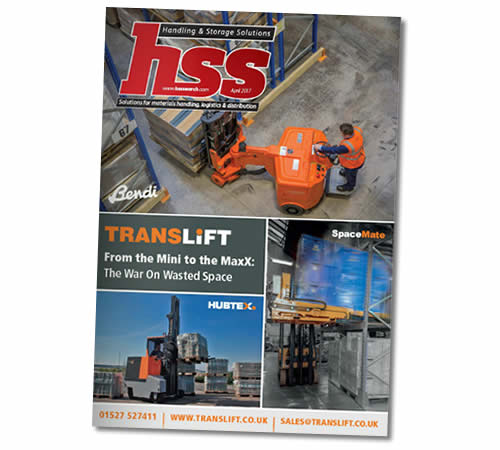

Telford’s International Centre was once again the venue for the FLTA’s Awards For Excellence ceremony. In what proved to be the most competitive category, INNOVATION, we were delighted to be presented with a rare “Highly Commended” award for the Translift SpaceMate.

At a third of the cost of an articulating truck and a fraction of a VNA, the SpaceMate can be added to ANY forklift, new or old, enabling pallet stacking in VNA aisles.

Stacking in sub 2m aisles is achieved using just one hydraulic function. Quick release fittings making it simple to add and remove – quickly transforming the forklift from normal to VNA duties.

If you have a question about Translift, our products or services then please contact us here. You can also call our team on 01527 527411 or email sales@translift.co.uk. Make sure to follow our social media pages on Facebook and Twitter to keep up-to-date with the latest news and events.